The only place you need to go for all your cellular concrete equipment and foam concentrate. Plus now we have our new versatile sub compact articulating loader to help on any jobsite.

Since 2011 Richway has been leading the way in bringing you innovative solutions for producing cellular concrete. Our cellular concrete equipment is designed to make it easy for you. We continue to advance technology and pave the way. And our CMX foam concentrate has stood the test of time. Used by hundreds of contractors around the world, it’s capable of handling a vast variety and the most demanding cellular concrete applications.

With nearly five decades of designing and manufacturing foam generation equipment, Richway is a leader in cellular concrete equipment servicing many industries including utility, infrastructure, mining, and precast. Designed from day one for producing cellular concrete, we build our machines from the axle up. From 1 yd³ projects to 100,000 yd³ projects we have the equipment, service, and support you need to get the job done.

Richway’s CMX foam concentrate was created in house for use in cellular concrete to give you a consistent, durable, and unyielding bubble that will perform in the most demanding applications. Plus, we blend our foam in house for the highest quality control and quick delivery for you.

With the recent introduction of our SCL-210, the first machine in our line of subcompact wheel loaders, Richway is offering contractors a powerful, versatile, and capable machine that was born, raised, and built in Iowa.

With nearly five decades of designing and manufacturing foam generation equipment, Richway is a leader in cellular concrete equipment servicing many industries including utility, infrastructure, mining, and precast. Designed from day one for producing cellular concrete, we build our machines from the axle up. From 1 yd³ projects to 100,000 yd³ projects we have the equipment, service, and support you need to get the job done.

Richway’s CMX™ foam concentrate was created in house for use in cellular concrete to give you a consistent, durable, and unyielding bubble that will perform in the most demanding applications. Plus, we blend our foam in house for the highest quality control and quick delivery for you.

With the recent introduction of our SCL-210, the first machine in our line of subcompact wheel loaders, Richway is offering contractors a powerful, versatile, and capable machine that was born, raised, and built in Iowa.

Since 2011 Richway has been leading the way in bringing you innovative solutions for producing cellular concrete. Our cellular concrete equipment is designed to make it easy for you. We continue to advance technology and pave the way. And our CMX foam concentrate has stood the test of time. Used by hundreds of contractors around the world, it’s capable of handling a vast variety and the most demanding cellular concrete applications.

Check out our YouTube videos to learn more about cellular concrete and to see our CreteFoamers in action.

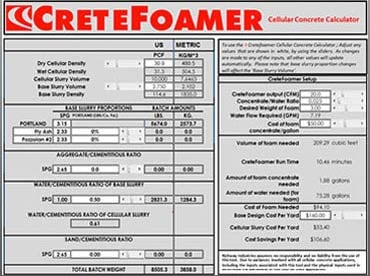

Download our free mix design calculator for cellular concrete. It will help you save time and hassle when creating mix designs and doing cost scenario analysis. It’s useful for determining batch weights, required amounts of water and concrete, and calculating your costs.

If you have any questions or need help about a product, feel free to contact us Mon – Fri 8-5pm CST.

If you have any questions or need help about a product, feel free to contact us Mon – Fri 8-5pm CST.

Website Designed by Running Robots

"*" indicates required fields